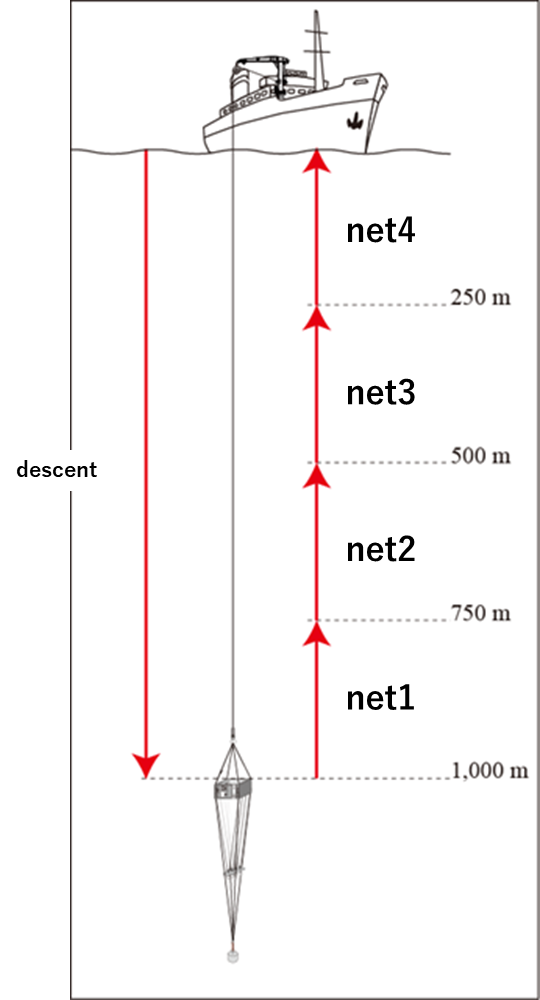

Figure 10 VMPS towing example

While the underwater station is being lowered, the depth sensor readings are continuously monitored on the onboard station monitor. As soon as the underwater station reaches the desired depth, the cable is hoisted and the towing begins. Since the plankton collection efficiency depends on the speed at which the net is moved, the cable is wound up at a constant speed to ensure that the collection efficiency does not vary during the tow. The net is opened and closed by sending an open/close signal from the on-board station at an arbitrary timing during the tow. Usually, a collection range (depth) is determined in advance, and the net is opened and closed when the underwater station passes through that depth. The net is sometimes monitored for water temperature, salinity, and other parameters, and the collecting area is determined based on these parameters. Also, when the underwater station is in the water, the ship must be maneuvered to avoid being separated from the station by currents and winds.

*Example of a Towing Net

An example of a VMPS tow net is shown in Figure 10. In this example, the net is opened and closed at three depths of 750, 500, and 250 meters during the ascent (tow) after the underwater station has been lowered to 1,000 meters. By doing so, the plankton community in four different ranges (0~250, 250~500, 500~750, and 750~1,000 meters) can be sampled separately in a single tow.

Figure 10: Example of VMPS towing