Dulse is a type of cold-sea seaweed

classified in the same red algae family as laver, and has a reddish-purple

color immediately after harvesting. It is said to be widely distributed along

the Atlantic coast of North America and in northern Europe. In Ireland and

Canada, dulse has long been eaten fresh as a salad, and its dried form has been

used as a seasoning. Thus far, the use of dulse has been limited to fresh or

dried products. Perhaps for this reason, academic research seems to be almost

entirely limited to nutritional findings on the raw algae or on their drying

characteristics. On the other hand, Japan has a technology for boiling and

salting seaweeds, which is rare in the world, and we have excellent knowledge

and much experience. Therefore, as a new direction for the development of new

applications, we have attempted to explore the characteristics of the material

and its suitability for use from a new, uniquely Japanese perspective.

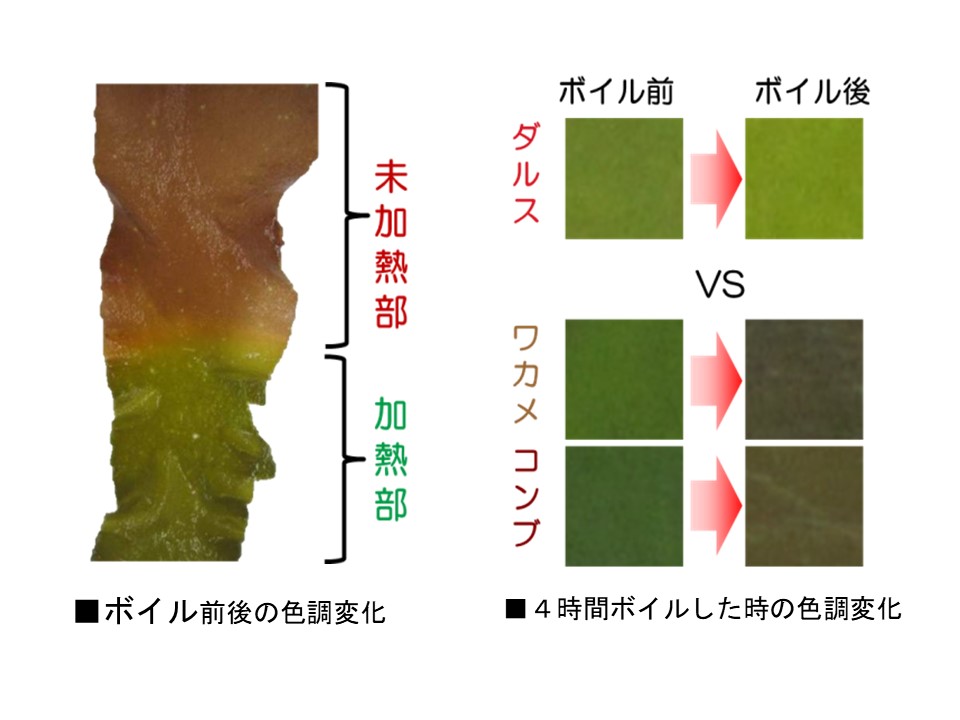

As mentioned above, dulse has a

reddish-purple color when raw, but it is not known what tint it develops when

boiled. We first observed the color change of dulse when it was heated in

boiling seawater. We found that dulse changed from the reddish-purple color of

the raw algae to a greenish-green color. However, there are many green-colored

seaweeds such as sea mustard and kelp, and vegetables such as chives and leeks,

which are commonly used in our daily lives. Therefore, we further investigated

to obtain a characteristic that is unique to dulse. As a result, we found that

the green color of dulse, which is produced by boiling and heating, has a

characteristic of being heat-resistant.

Only some of the results are shown here,

though, boiling commercially available boiled and salted kelp and sea mustard

in artificial seawater at 95°C for 4 hours causes grayish-browning and color

degradation, but a similar experiment conducted on boiled and salted dulse

confirmed that the beautiful green color was retained even after 4 hours of

boiling. Next, in order to determine the extent to which this green color is

resistant to heat, we observed the color tone after retort heating. Although

the results are not shown here, it was confirmed that the green color of dulse,

which had been once turned green by boiling in artificial seawater at 95°C, was

not significantly degraded even after heating, when it was packed in packaging

materials with 20 times the amount of the same solution and retorted at 120°C

for 10 minutes. These results indicate that the green color of dulse can be

retained even after retort heating, indicating that dulse has excellent heat

resistance.

■left figure ボイル前後の色調変化:

Color change before and after boiling

未加熱部: unheated part 加熱部: heated part

■right figure4時間ボイルした時の色調変化:

Color tone change after boiling for 4 hours

ボイル前: before boiling ボイル後: after boiling

ダルス: dulse ワカメ: sea mustard コンブ: kelp